Cartridge bottom brackets started to replace the adjustable types back in the late 80s/early 90s, so these are much more common on bikes with indexed shifting. If the bearings have a ton of play or make clicking sounds as you pedal, then the bottom bracket is toast. I can show you how to remove and replace a cartridge bottom bracket in this little tutorial. First you need a crank puller, a bottom bracket tool, and something to remove the crank bolts (this procedure is impossible without the right tools, but very easy if you have them). You'll probably also want a nice big wrench or breaker bar for leverage with the bottom bracket tool. Well let's get started:

First remove the crank bolts. This bike uses 8mm Allen bolts (a 5/16" Allen key also fits, but might strip them under high torque due to their looser fit).

Now with the bolts removed you can see the threads for the crank puller to screw into:

Thread the crank puller all the way in and remove the cranks:

Now it's time to use the bottom bracket tool. It's a large tool with 20 splines to fit most bottom brackets (there are exceptions like Phil Wood or Shimano Dura-Ace/XTR, these need something special). I like to put a big 15/16" box end wrench on the tool, but use whatever you like for leverage. I loosen up one side first:

Then remove the other piece:

Keep in mind that the drivetrain side is probably reverse threaded. Now just remove the piece remaining in the frame (I don't think it matters which piece you remove first) and you're done. Here are all the pieces that I removed (along with the tools I used):

The bearings in these cartridge units are generally not serviceable, so you just replace the whole cartridge if they go bad. Here's what the bearings look like with the dustcap removed:

A replacement bottom bracket goes in the opposite way, just clean and grease the frame's threads and put lots of torque on the main piece. The little plastic cup on the other side only needs to be snug tight. You shouldn't have to adjust anything, provided that you used the same size replacement.

There are 3 variables when buying a replacement bottom bracket: thread size, bottom bracket shell width, and spindle length. Most frames are English threaded (1.375"-24tpi) with 68mm wide shells (some mountain bikes have 73mm shells, and Italian frames are 70mm). Your crankset, however, determines the spindle length instead of your frame. Remove your bottom bracket and measure it to verify all of its dimensions before you buy another one to be sure you get the right size replacement.

Got a nice old bike in your garage? Maybe I can help you get it working again.

Saturday, July 28, 2012

Thursday, July 26, 2012

Wrapping Handlebars

Wrapping handlebar tape on drop bars is pretty easy, but I'll show a few tricks to give you a more professional look. Start by removing any old tape and cleaning the bars:

Next measure a piece that's just long enough to cover the back of the brake lever and stick it in place:

Before you start wrapping the bars it's a good idea to cut an angle in the tape so that there won't be a big bump where the tape starts. This also ensures you won't have a bare spot on the bottom of the handlebars.

Now you can start wrapping. I like to start from the bottom and work my way to the top. It's a very good idea to wash your hands right before you start to avoid getting the tape dirty and contaminating the sticky backside of the tape.

Now comes the tricky part. Once you get to the curved section of the bars you have to overlap the tape much more. This is to prevent a gap from showing on the outside of the curve. When I get to the brake lever I like to just continue wrapping around the extra piece to make it look like it's a continuous part of the tape:

Again, the tape must be pulled tight around the curves because this is the most likely place for it to shift around. It's a good idea to check for gaps on the outside part of the curves now since you can still easily retape it. Once you get to the end you should cut another bevel into the tape:

After that you just need to pull the tape nice and tight and secure it with lots of electrical tape (or finishing tape if it came with your kit). Here's the completed result:

Next measure a piece that's just long enough to cover the back of the brake lever and stick it in place:

Before you start wrapping the bars it's a good idea to cut an angle in the tape so that there won't be a big bump where the tape starts. This also ensures you won't have a bare spot on the bottom of the handlebars.

Now you can start wrapping. I like to start from the bottom and work my way to the top. It's a very good idea to wash your hands right before you start to avoid getting the tape dirty and contaminating the sticky backside of the tape.

It's also very important to keep tension on the tape the entire time that you are wrapping it around the bars. If you wrap it too loose then the tape will shift around and unravel. Try to overlap the tape by the same amount for a neat professional look:

Again, the tape must be pulled tight around the curves because this is the most likely place for it to shift around. It's a good idea to check for gaps on the outside part of the curves now since you can still easily retape it. Once you get to the end you should cut another bevel into the tape:

After that you just need to pull the tape nice and tight and secure it with lots of electrical tape (or finishing tape if it came with your kit). Here's the completed result:

Thursday, July 19, 2012

Vintage Fuji Rebuild

In my previous post I showed you how I took apart an old Japanese road bike for restoration. Now I'll show you how I put it back together. The process is basically the reverse of removal so I won't show every nut and bolt again, but I will try to explain how to make the necessary adjustments so that your bike rides better than before. First I reinstalled the fork. To do this I cleaned the bearings, packed them with marine grease, and slid the fork in:

Then I adjusted the headset by screwing the top race almost all the way down, then tightening the lockring and then the top nut to lock it in place (your headset probably won't have an additional lockring so you would just secure the top race's adjustment with the top nut). Here are the headset pieces in the order which they are installed:

There should be no play in the fork, but it must also spin easily. Next I wanted to work on the bike upside down so I installed the saddle and handlebars (without the brake cables installed so that I don't kink them....I need a work stand). Now I could install the bottom bracket:

The adjustment is similar to the headset, you just screw in the adjustable cup until the play is gone and then tighten down the lock ring. I prefer to adjust these a little tight at first because they seem to loosen up a bit on their own. Now comes the cranks and pedals:

There are a few necessary adjustments to give you good working brakes. First you need to make sure the pads are centered on the rim:

My camera likes natural light so much better. Anyway once all the pads are centered and securely tightened you can center the brake itself. You can loosen the mounting nut and rotate the brake arms until the pads are both an equal distance from the rim, then tighten the nut down:

Now comes the cable adjustment. The brake cable attaches to a straddle wire with these centerpull brakes, so you have to thread it through the little bolt on the cable hanger:

Once the cable is installed you just need to pull all the slack out of the inner wire (and pull the straddle wire up in this case), then tighten the bolt and nut together as shown. Make further adjustments with the barrel adjuster to bring the pads a desirable distance from the rim for good stopping power. Here are all the cables reinstalled (I removed them all for cleaning and inspection since sticky or frayed cables don't work well):

Next I reinstalled the rear derailleur:

Disassembled for cleaning:

Cleaned, regreased, and adjusted:

Finally I reinstalled the freewheel, chain, and the original tires so I could test ride it and fine tune the brakes and shifters. Here's the near complete bike:

New tires and tape:

Then I adjusted the headset by screwing the top race almost all the way down, then tightening the lockring and then the top nut to lock it in place (your headset probably won't have an additional lockring so you would just secure the top race's adjustment with the top nut). Here are the headset pieces in the order which they are installed:

There should be no play in the fork, but it must also spin easily. Next I wanted to work on the bike upside down so I installed the saddle and handlebars (without the brake cables installed so that I don't kink them....I need a work stand). Now I could install the bottom bracket:

The adjustment is similar to the headset, you just screw in the adjustable cup until the play is gone and then tighten down the lock ring. I prefer to adjust these a little tight at first because they seem to loosen up a bit on their own. Now comes the cranks and pedals:

The crank bolts themselves will tighten the cranks onto the spindle. These should be at least 25 ft-lbs, but if you don't have a torque wrench you can just stop after you feel a noticeable increase in resistance (this means the crank is fully seated). The pedals should also be very tight, they go on with a 15mm wrench.

Next I temporarily put the wheels on so I could work on the brakes:

My camera likes natural light so much better. Anyway once all the pads are centered and securely tightened you can center the brake itself. You can loosen the mounting nut and rotate the brake arms until the pads are both an equal distance from the rim, then tighten the nut down:

Now comes the cable adjustment. The brake cable attaches to a straddle wire with these centerpull brakes, so you have to thread it through the little bolt on the cable hanger:

Once the cable is installed you just need to pull all the slack out of the inner wire (and pull the straddle wire up in this case), then tighten the bolt and nut together as shown. Make further adjustments with the barrel adjuster to bring the pads a desirable distance from the rim for good stopping power. Here are all the cables reinstalled (I removed them all for cleaning and inspection since sticky or frayed cables don't work well):

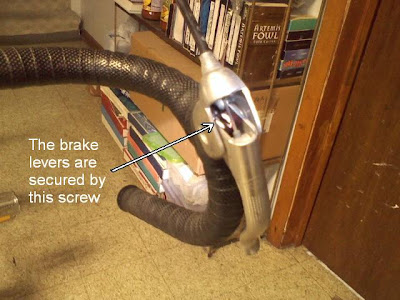

If your brake levers themselves are loose, then now would be as good a time as any to tighten them down:

Next I reinstalled the rear derailleur:

After that I repacked the wheel hubs (not the most efficient way to do things but whatever):

Disassembled for cleaning:

Cleaned, regreased, and adjusted:

New tires and tape:

Tuesday, July 17, 2012

Vintage Fuji Teardown

This is going to be a long post. I did a complete restoration of a

nice old Fuji Sports 12, and I can show you a bolt by bolt teardown to

its bare frame. I prefer to completely disassemble a very old bike

before putting it to serious use. This way I can inspect every part and

know everything was properly assembled when I go for a long ride. Here's

the bike:

It has dry rotted tires, misadjusted brakes, and possibly several hidden problems so let's get started. First I removed the seatpost:

After this I like to remove the handlebars and stem, so first I disconnected the brake cables:

Next I loosened the clamp that holds the shifters to the handlebars. This is just a large philips screw (a #2 if I remember correctly):

Now I can loosen the stem bolt and remove the bars:

I had to smack the bolt down with a hammer before the stem would move freely. After that I just had to remove the 3 little chrome clamps that hold the rear brake cable to the frame, and then the handlebars came right off:

Next I wanted to remove the cranks and bottom bracket. First I removed the pedals:

Then I unscrewed the dustcaps covering the crank bolts (one of the rare times a penny can be useful for anything...):

Now I can remove the crank bolts:

These came out pretty easily, but sometimes they can be really stuck in there. Anyway it's time to use the crank puller. I showed the Park Tool version in an earlier post, so this time I wanted to show the generic one. First you need to unscrew the part the pushes into the bottom bracket spindle, then thread the puller into the crank. Make sure it's fully engaged:

Now you can tighten the piece you originally unscrewed until the crank pops off:

With the cranks off you can remove the bottom bracket. First unscrew the lockring on the left side:

Now you can remove the adjustable cup. There are lots of different styles of these. This particular one has 2 large slots for a big flat bladed screwdriver to fit. I used a hammer and punch to get it started:

Once the left side cup is out you can slide out the spindle. The last step is to remove the right side cup. Remember this one is reverse threaded on most frames:

This one came out extremely easily, and it might even have loosened up on its own had I not bothered to remove it. With the cranks and bottom bracket gone I decided to remove the fork next. First I had to disassemble the headset:

If your bike has one of these brackets for the brake cable it's a good idea to hold it while unscrewing the top locknut to prevent damage to the threads on the fork. With the locknut off there was an additional lockring underneath the bracket:

I guess this is an extra measure to keep the headset from coming loose. With the lockring unscrewed the bearing race can be unscrewed by hand, and the fork will then slide right out:

Next I removed the front wheel and the brake from the fork:

After that I decided to remove the rear derailleur to clean and oil the moving parts. First I had to remove the rear wheel:

Next I unbolted the shift cable (8mm hex bolt):

Then the mounting bolt:

On most derailleurs you would have to break the chain, but this one has a split pulley cage so I could just unhook it from the tension pulley. Here is the frame as it currently sits:

Next I removed the parcel rack and the chain for a thorough cleaning:

Finally I removed the tires from the wheels. I also unscrewed the freewheel in order to repack the bearings:

I caught a few potential problems by completely disassembling the bike. The pedals were rather loose, the right side bottom bracket cup was way too loose, and the rear wheel bearings were way too tight. Also, by removing the fork and bottom bracket I can clean and regrease the bearings to greatly extend their service life. In my next post I will show you how I put this bike back together.

It has dry rotted tires, misadjusted brakes, and possibly several hidden problems so let's get started. First I removed the seatpost:

After this I like to remove the handlebars and stem, so first I disconnected the brake cables:

Next I loosened the clamp that holds the shifters to the handlebars. This is just a large philips screw (a #2 if I remember correctly):

Now I can loosen the stem bolt and remove the bars:

I had to smack the bolt down with a hammer before the stem would move freely. After that I just had to remove the 3 little chrome clamps that hold the rear brake cable to the frame, and then the handlebars came right off:

Next I wanted to remove the cranks and bottom bracket. First I removed the pedals:

Then I unscrewed the dustcaps covering the crank bolts (one of the rare times a penny can be useful for anything...):

Now I can remove the crank bolts:

These came out pretty easily, but sometimes they can be really stuck in there. Anyway it's time to use the crank puller. I showed the Park Tool version in an earlier post, so this time I wanted to show the generic one. First you need to unscrew the part the pushes into the bottom bracket spindle, then thread the puller into the crank. Make sure it's fully engaged:

Now you can tighten the piece you originally unscrewed until the crank pops off:

With the cranks off you can remove the bottom bracket. First unscrew the lockring on the left side:

Now you can remove the adjustable cup. There are lots of different styles of these. This particular one has 2 large slots for a big flat bladed screwdriver to fit. I used a hammer and punch to get it started:

Once the left side cup is out you can slide out the spindle. The last step is to remove the right side cup. Remember this one is reverse threaded on most frames:

This one came out extremely easily, and it might even have loosened up on its own had I not bothered to remove it. With the cranks and bottom bracket gone I decided to remove the fork next. First I had to disassemble the headset:

I guess this is an extra measure to keep the headset from coming loose. With the lockring unscrewed the bearing race can be unscrewed by hand, and the fork will then slide right out:

Next I removed the front wheel and the brake from the fork:

After that I decided to remove the rear derailleur to clean and oil the moving parts. First I had to remove the rear wheel:

Next I unbolted the shift cable (8mm hex bolt):

Then the mounting bolt:

On most derailleurs you would have to break the chain, but this one has a split pulley cage so I could just unhook it from the tension pulley. Here is the frame as it currently sits:

Next I removed the parcel rack and the chain for a thorough cleaning:

Finally I removed the tires from the wheels. I also unscrewed the freewheel in order to repack the bearings:

I caught a few potential problems by completely disassembling the bike. The pedals were rather loose, the right side bottom bracket cup was way too loose, and the rear wheel bearings were way too tight. Also, by removing the fork and bottom bracket I can clean and regrease the bearings to greatly extend their service life. In my next post I will show you how I put this bike back together.

Subscribe to:

Comments (Atom)